To hold a sample, one can either clamp it (while controlling the clamping force), or adhere to something. Each of our devices implements one or the other option. Moreover, a control over the amount of material to be removed is essential to avoid occasionally removing too much.

The polishing itself, as well as microscopy of the amber inclusions and their storage, are discussed in a paper

The latest paper describing the method is published in Palaeoentomology:

If you study tiny amber fossils and wish to use our method of preparation, you can request the current set of holding tools from us by just writing an email to Dmitry (see 'About authors' section). We will send them to you free of charge.

You may also try to use this documentation to manufacture them yourself.

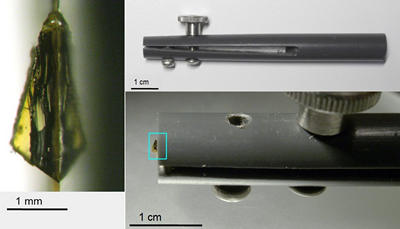

Here is a toolset which we currently use. Below it you may find other tools which we used and abandoned, but you may still find them useful for some task.